Turnkey conveyor belt system with fully automatic loading station

This year, KÖBO ECO>PROCESS GmbH has once again succeeded in convincing a customer of our capabilities.

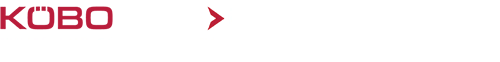

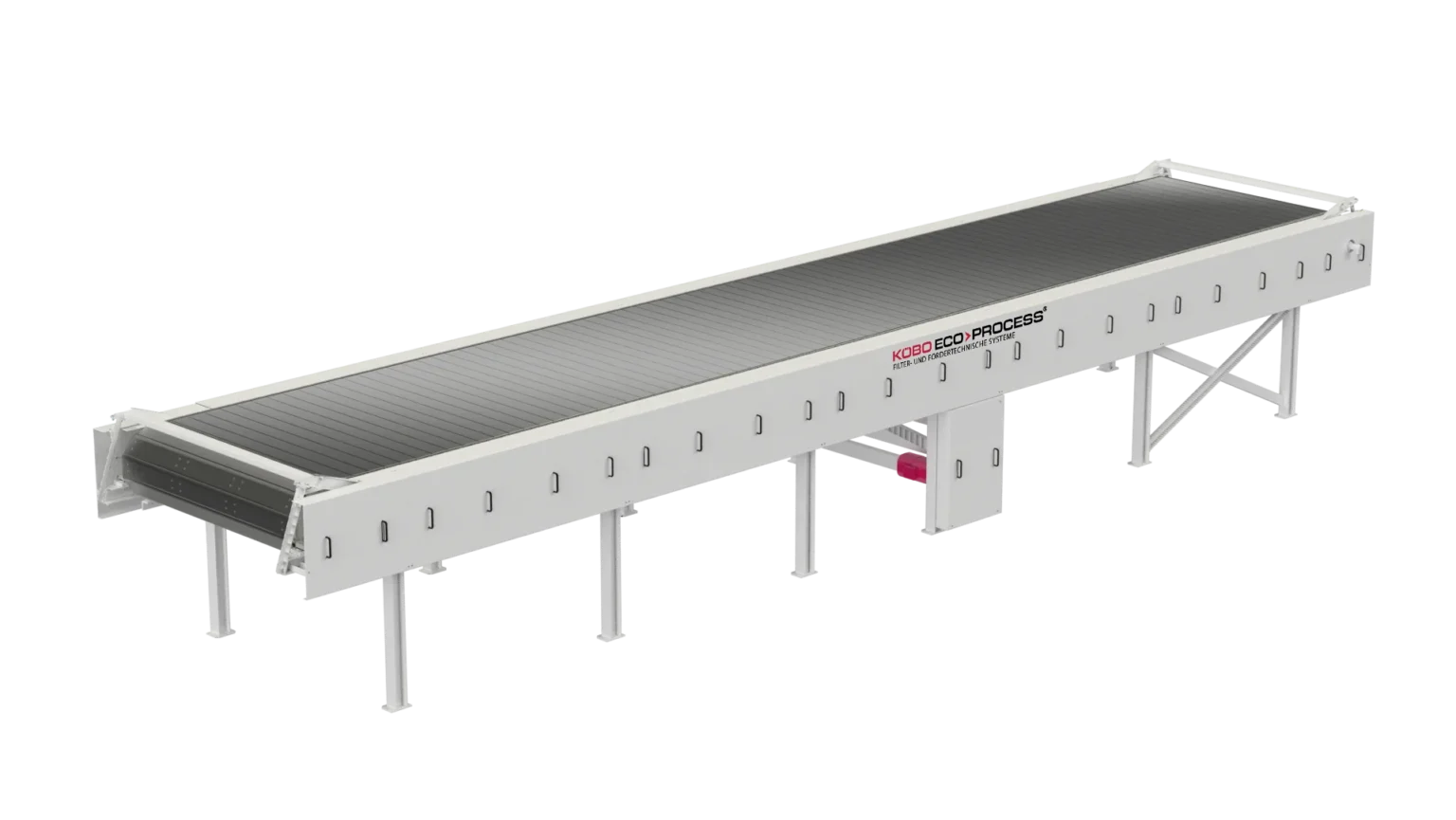

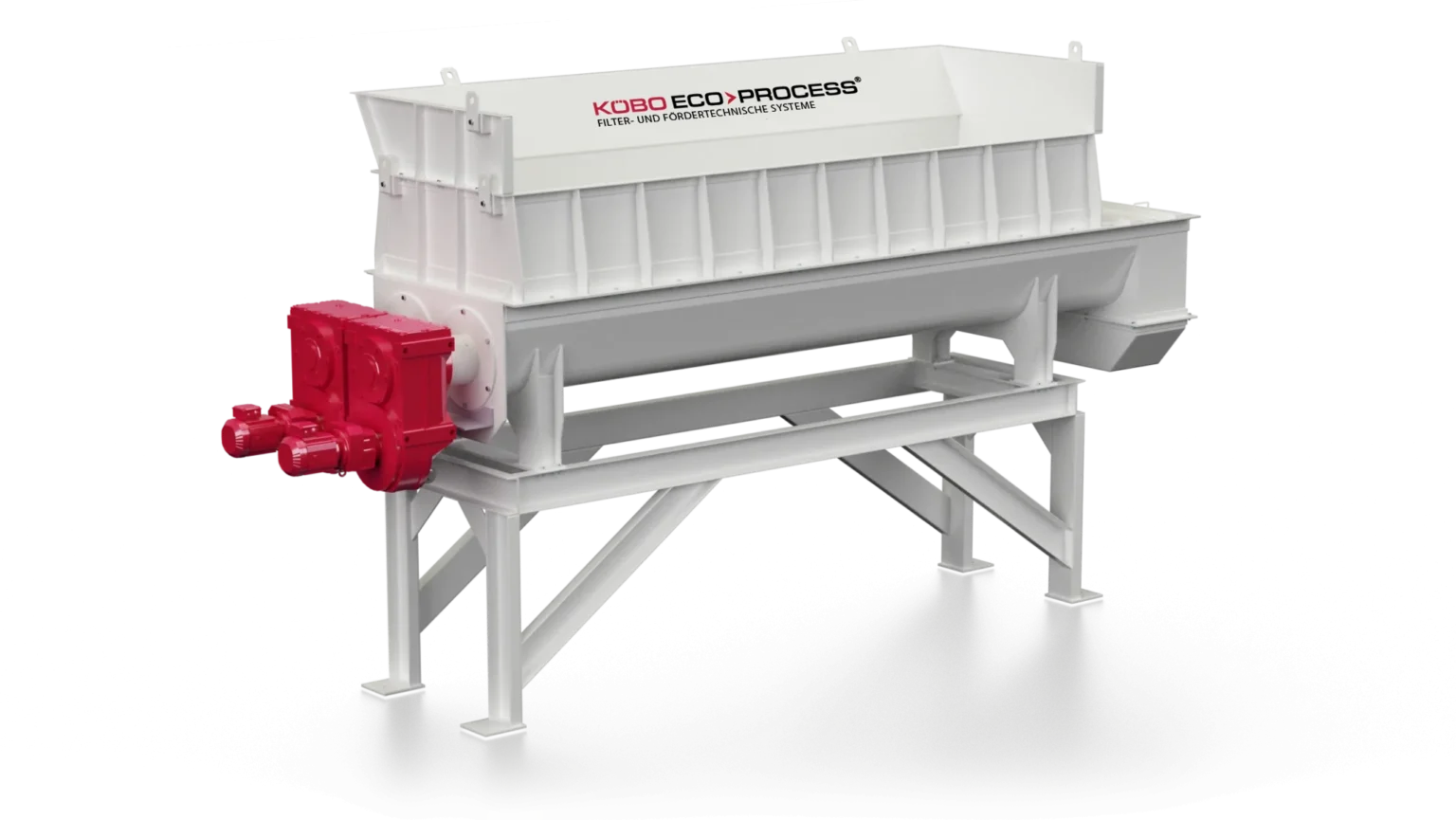

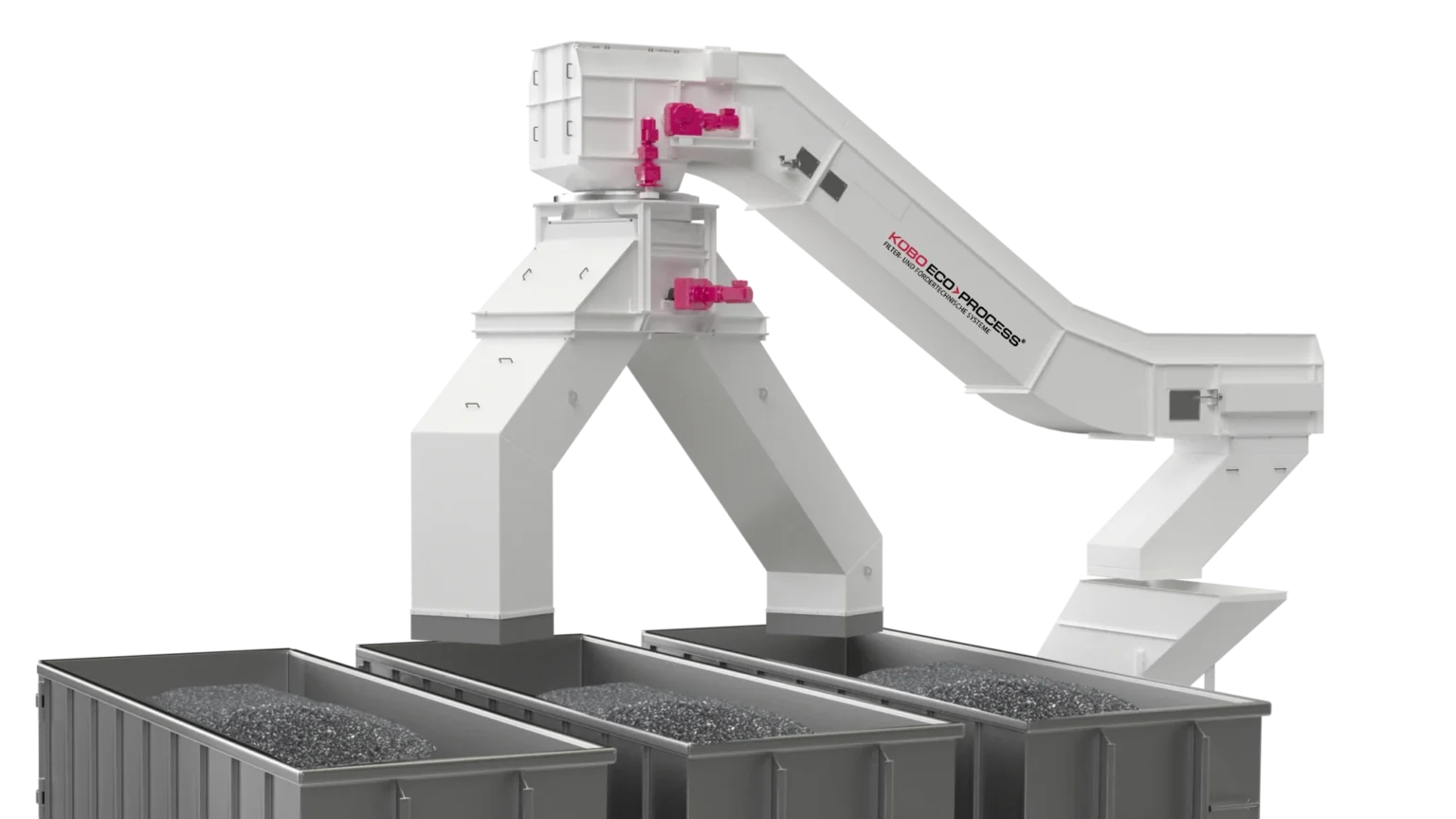

We planned and successfully implemented a turnkey conveyor belt system together with a fully automatic loading station for the removal of punching scrap from the forming processes for steel and aluminum sheets.

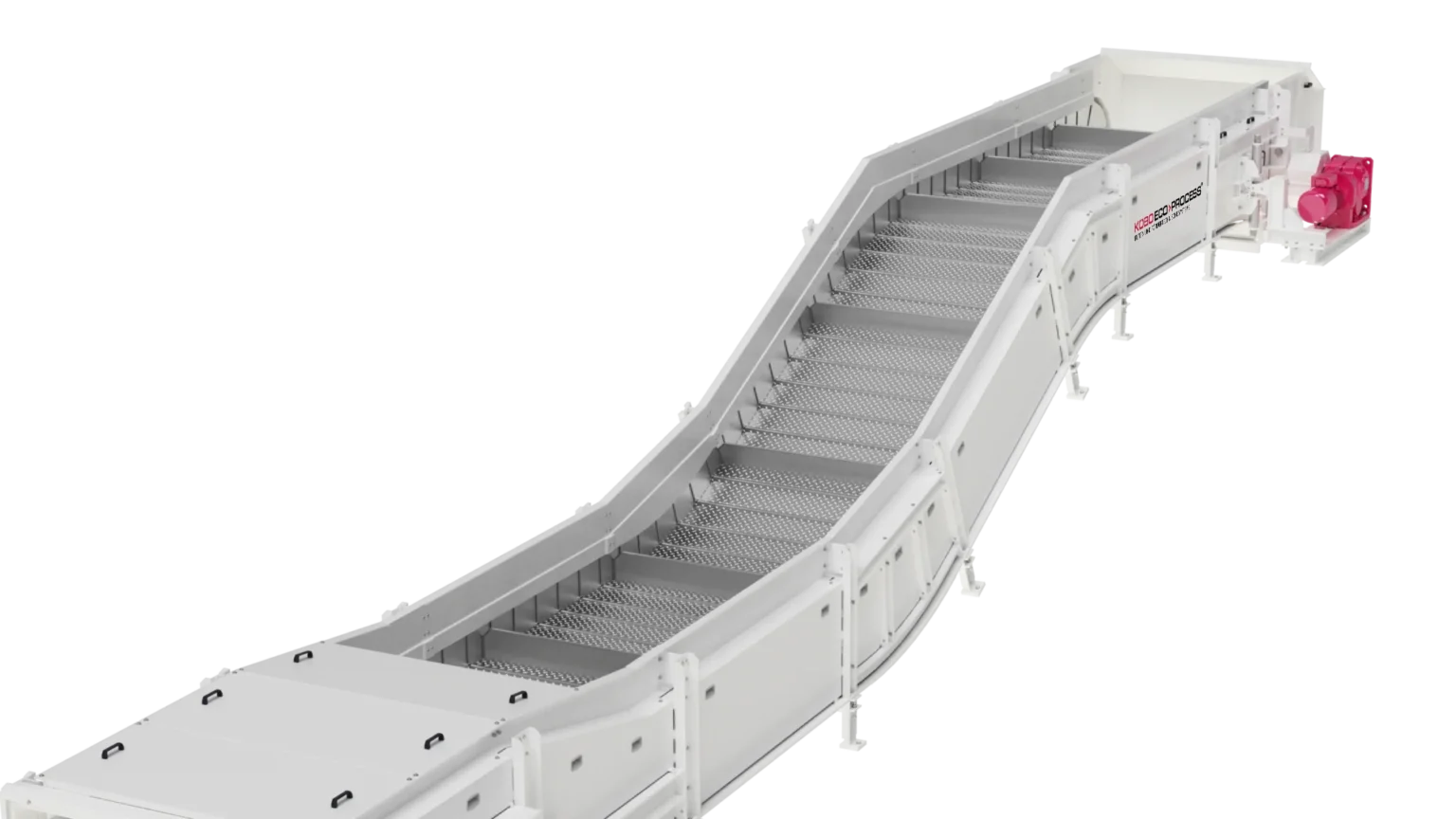

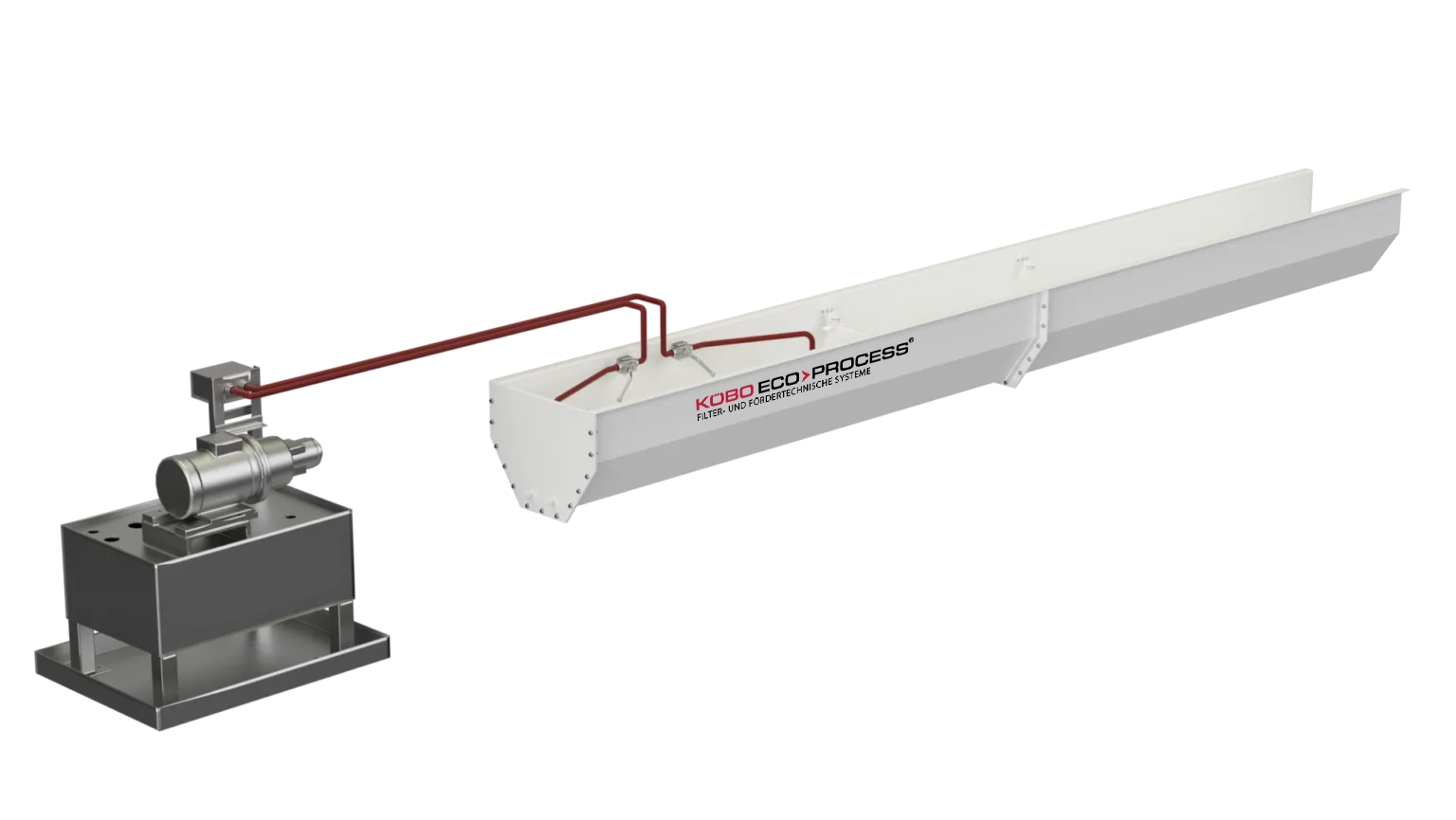

Among other things, hinged belt conveyors and swivel chutes were installed, with an additional conveyor path enabling materials to be loaded by type.

Using movable conveyors and special rotating chutes, it was possible to evenly fill a total of four wagons in the loading hall.

The total length of the hinged belt conveyors installed is 120 meters, with a belt width of 1500 mm.

This makes it possible to remove up to 44 tons of aluminium stamping scrap in one hour!

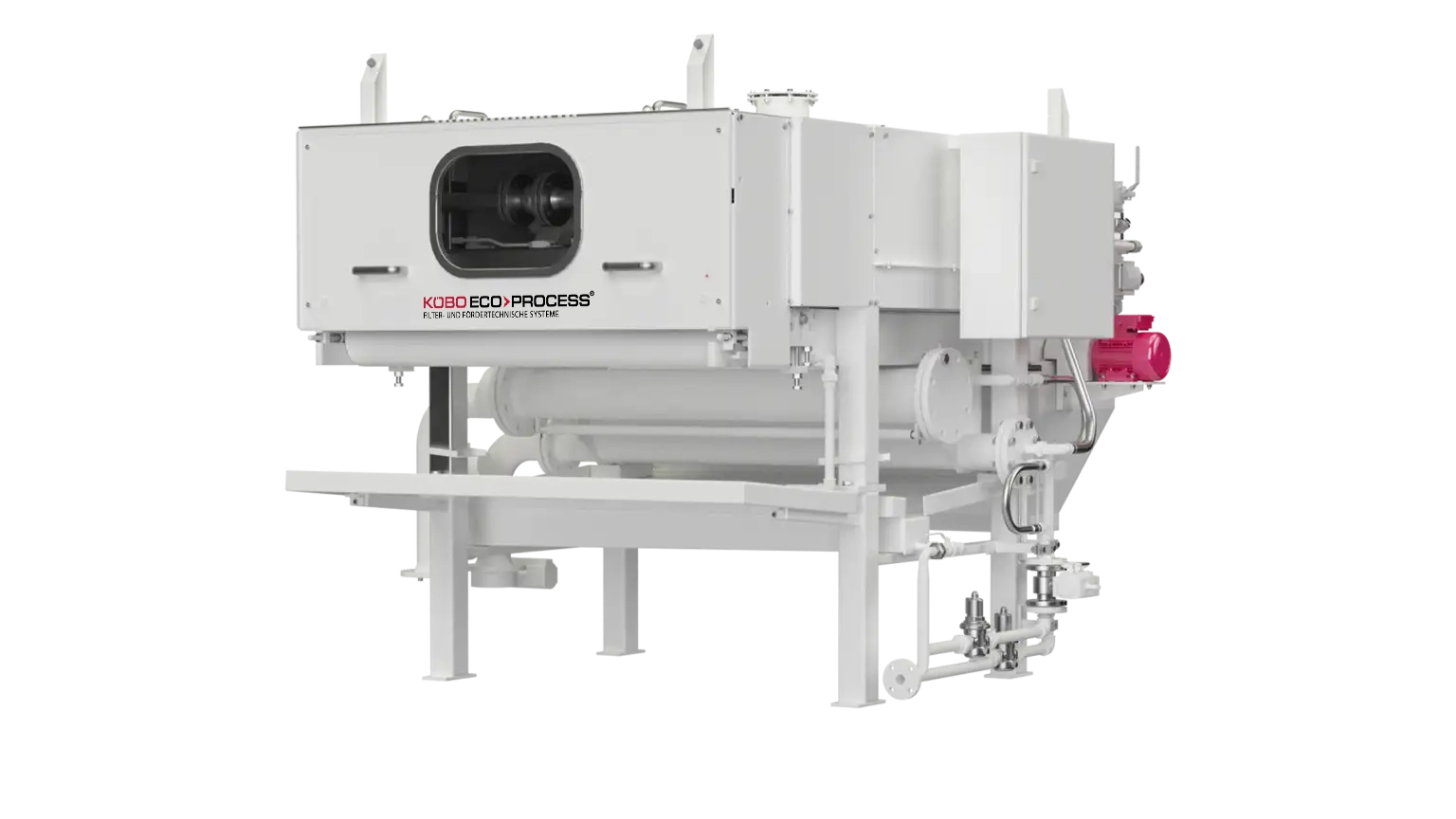

Our conveyor system ensures that resources are used responsibly, which benefits not only our customers but also the environment.