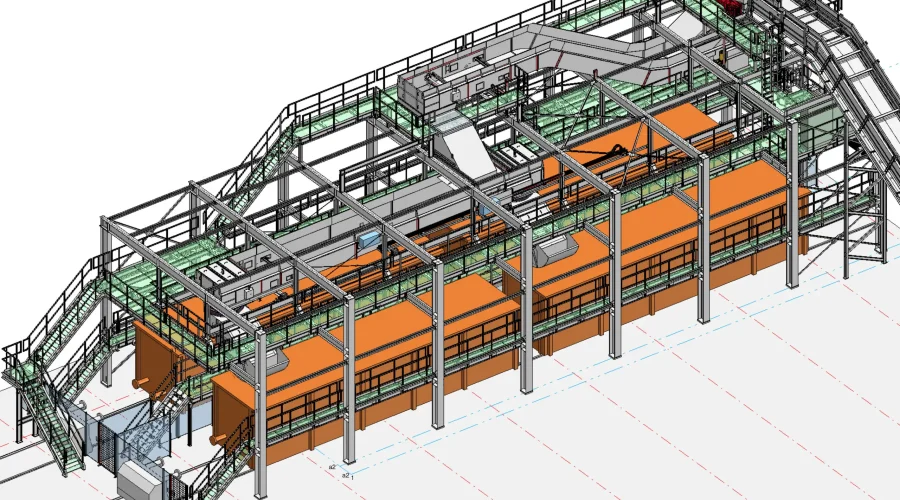

New plant in Untertürkheim

KÖBO ECO>PROCESS GmbH is a renowned company in the field of mechanical engineering, specializing in filter and conveyor technology.

Our outstanding position in the industry is undisputed.

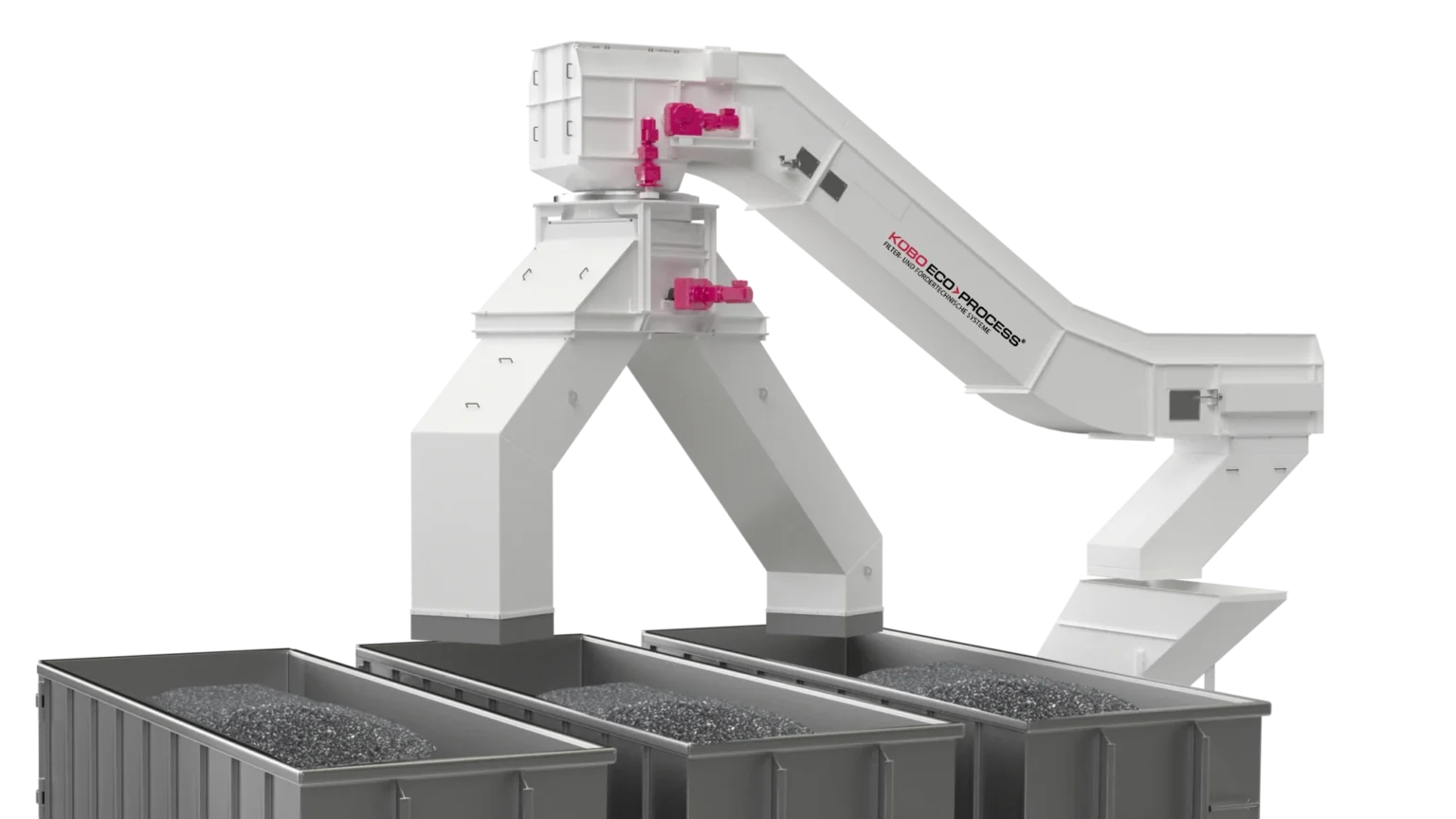

Most recently, a well-known car manufacturer from Germany benefited from our expertise and many years of experience in this field and commissioned us to design and install a cutting emulsion filter system.

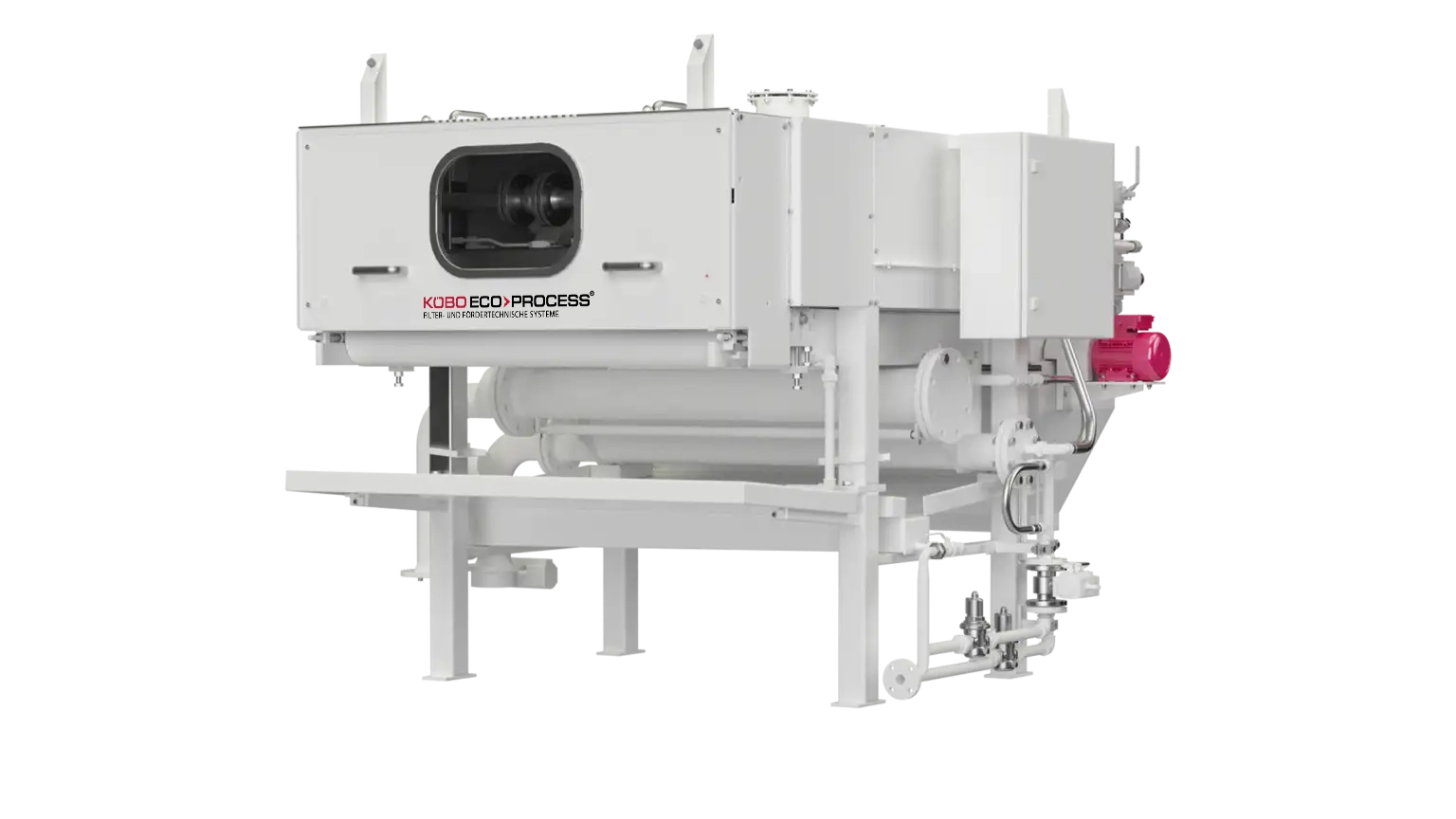

The primary function of the cooling lubricant filter system is to ensure that the processing machines are supplied with the cleaned and temperature-controlled medium.

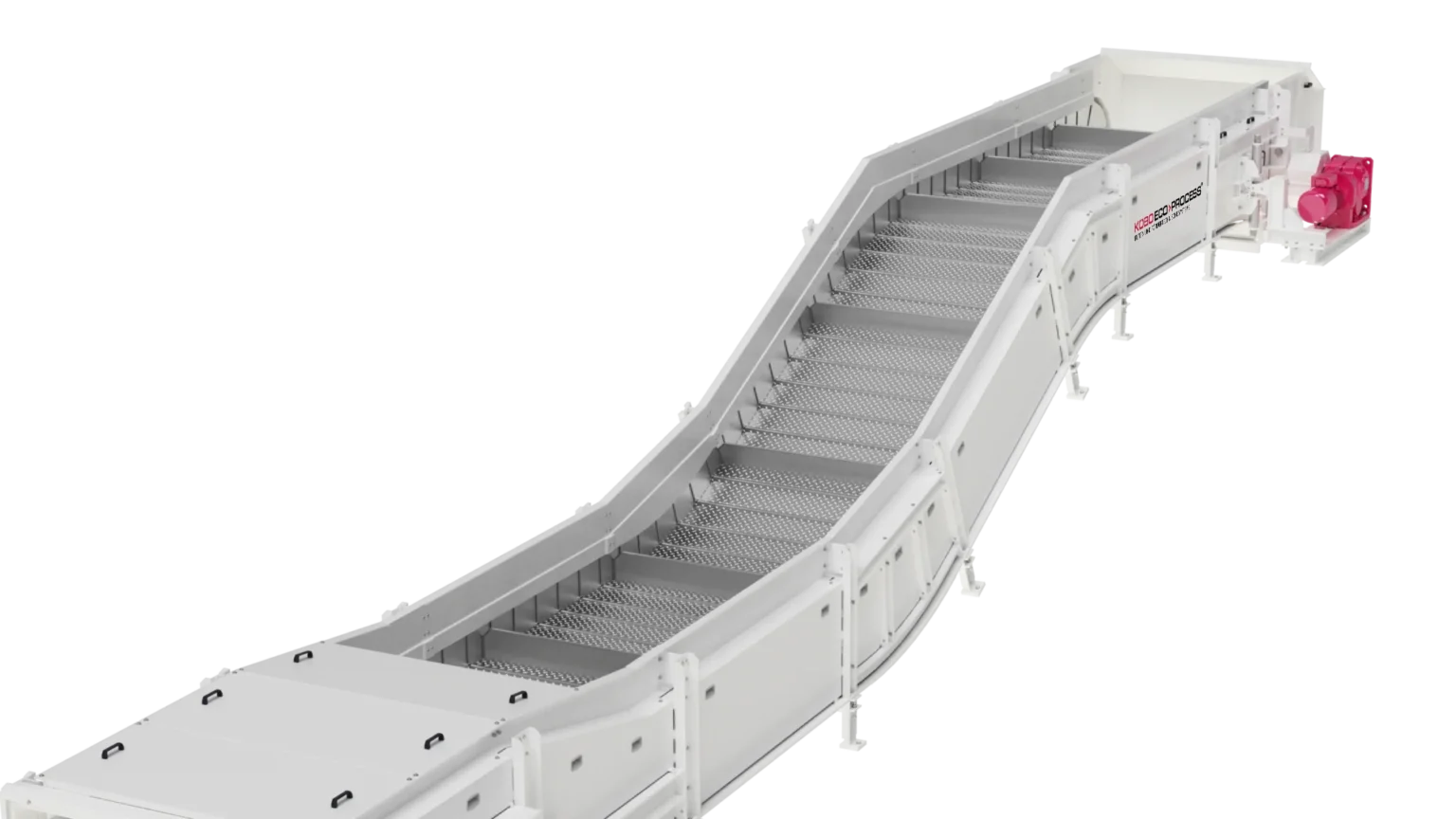

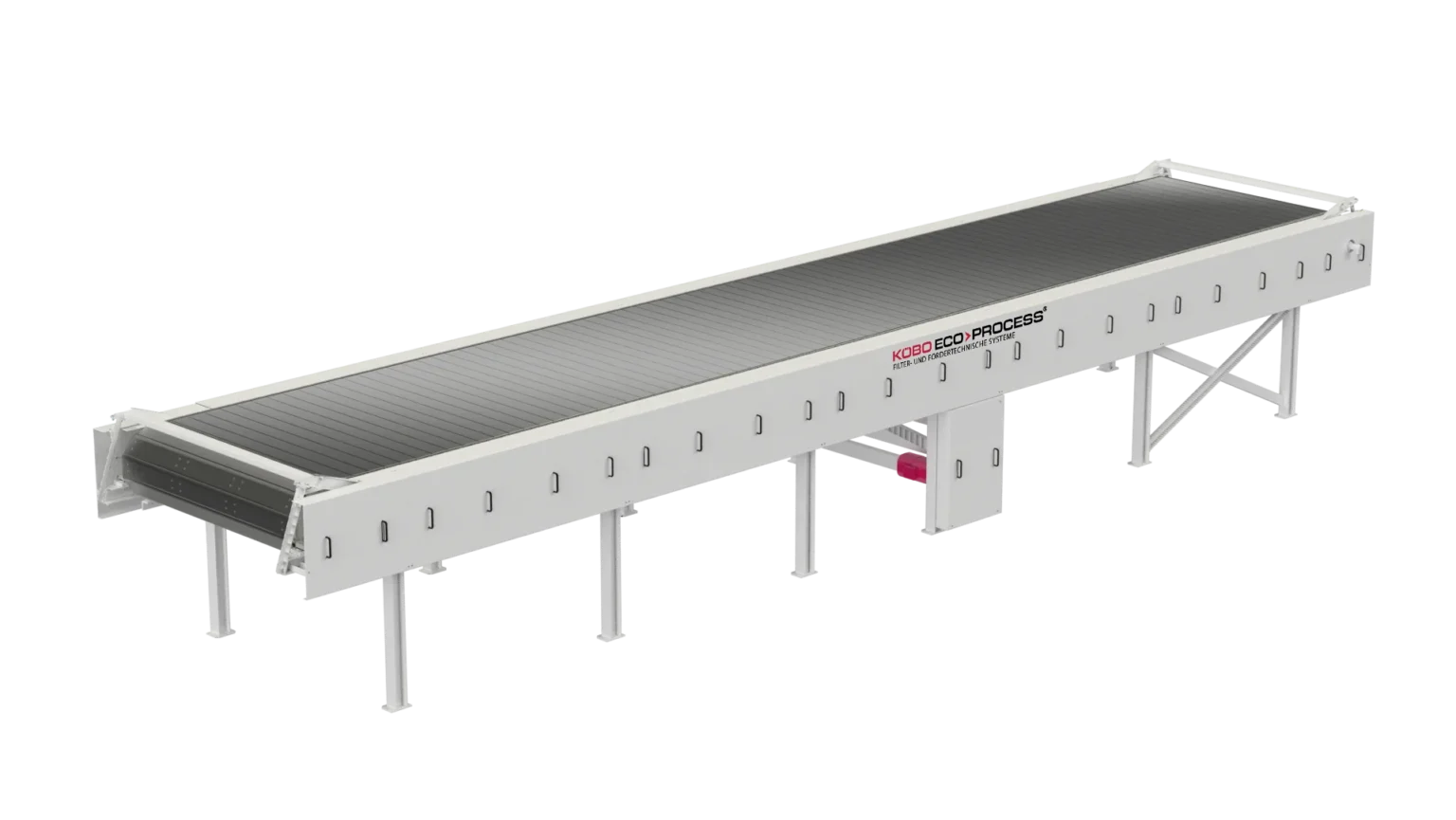

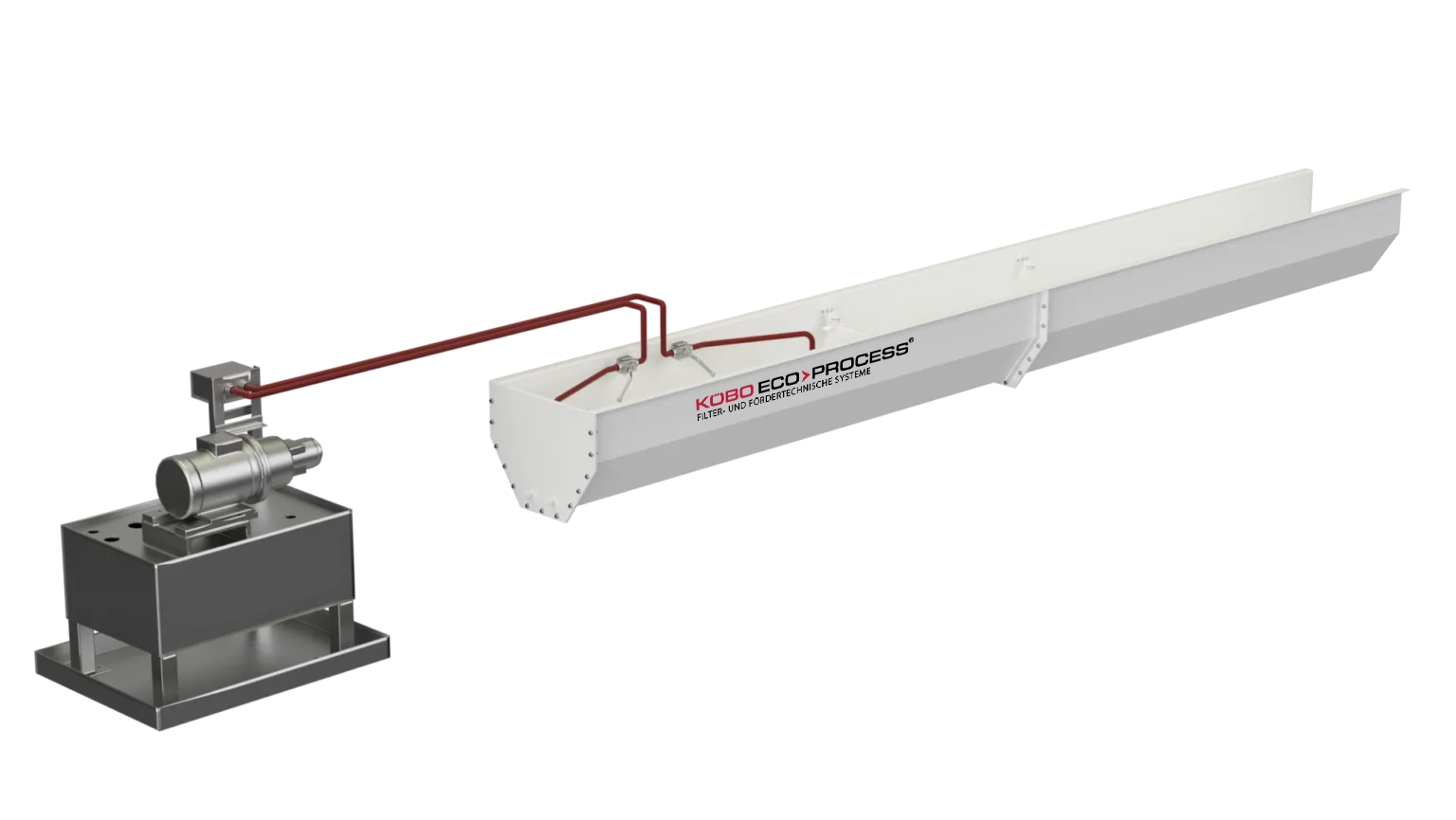

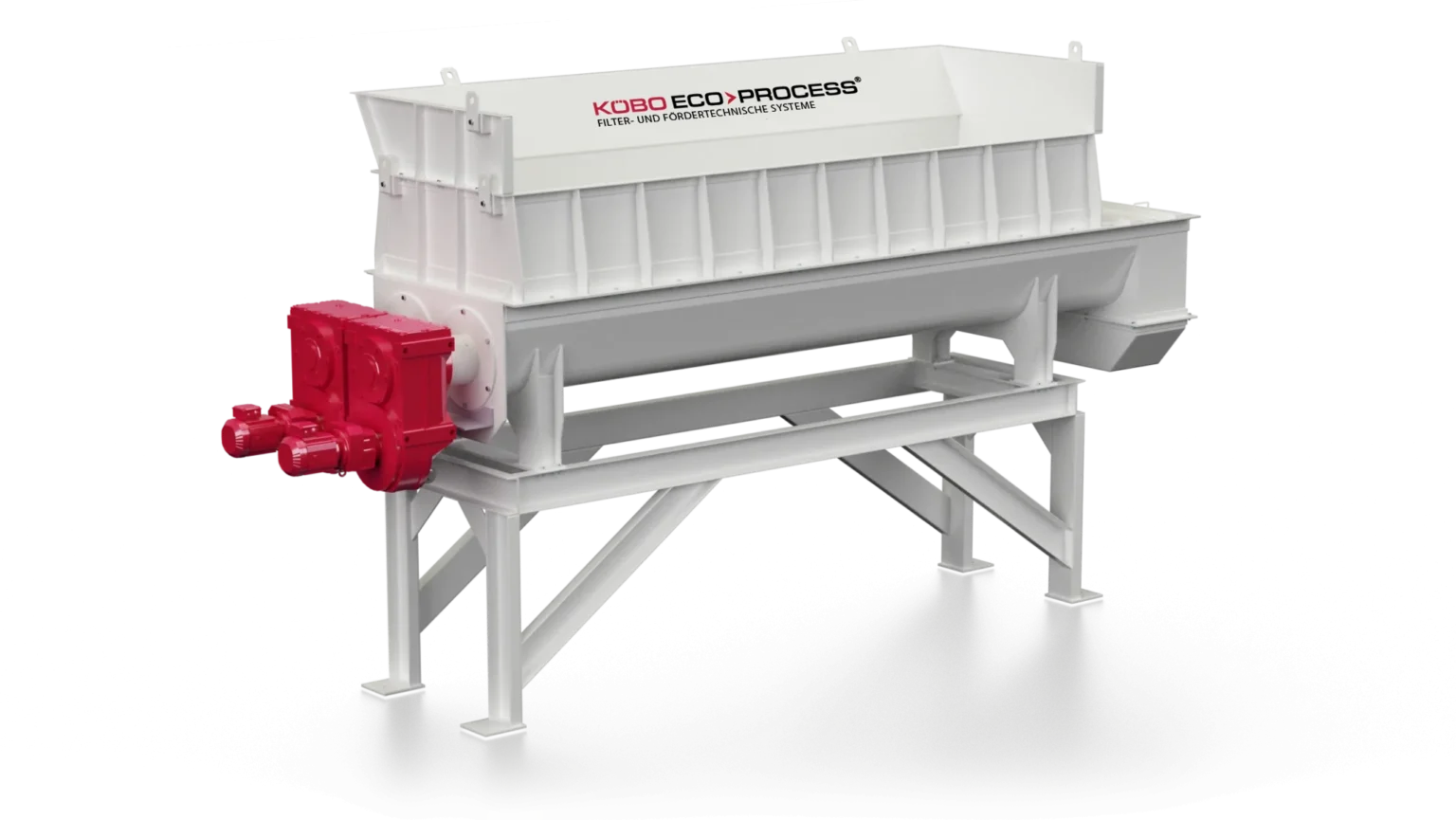

The system has two discharge containers, each with a volume of 60m³, which can also be used individually by means of appropriate shut-offs. Filter pumps suck the cooling lubricant out of the discharge containers and supply two pressure belt filters (DBF)in which the impurities from the cooling lubricant are retained.

The regeneration of the filters is fully automated.

The cleaned cooling lubricant flows from the filters into the clean tank, with some of the cleaned cooling lubricant flowing back into the discharge containers.