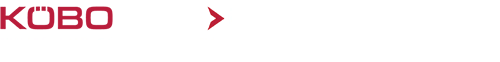

Completed plant in Kecskemet

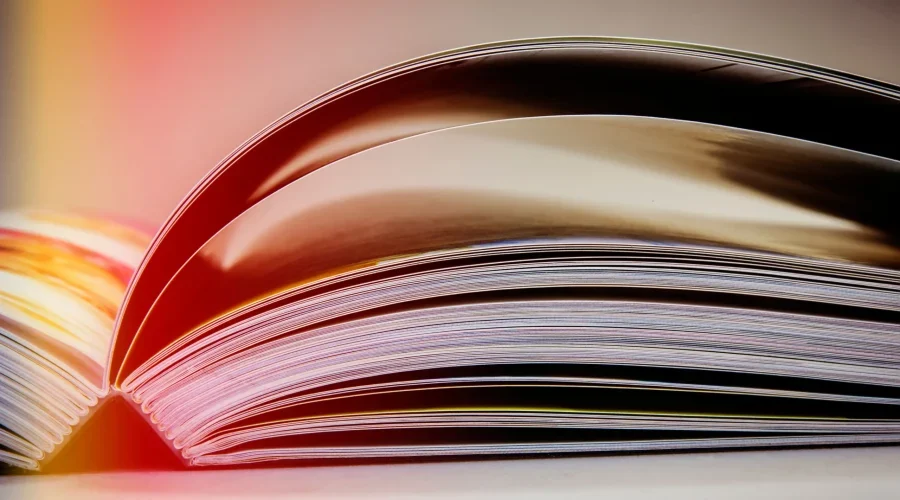

KÖBO ECO>PROCESS GmbH is one of the leading mechanical engineering companies in the field of filter and conveyor technology!

We have made it our mission to support our customers in the needs-based planning, implementation and commissioning of their system.

Our customers throughout Europe benefit from our expert knowledge and first-class service.

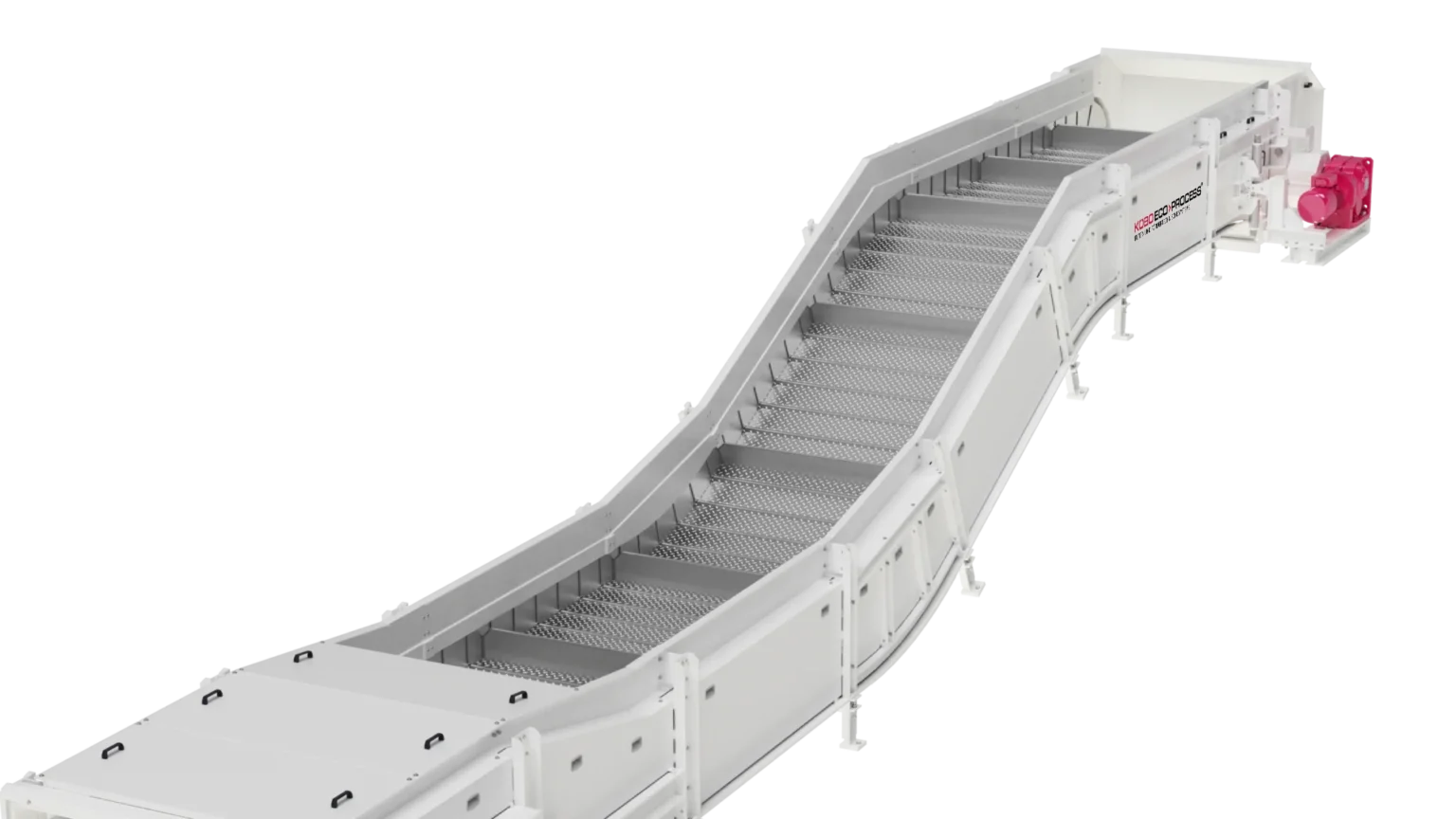

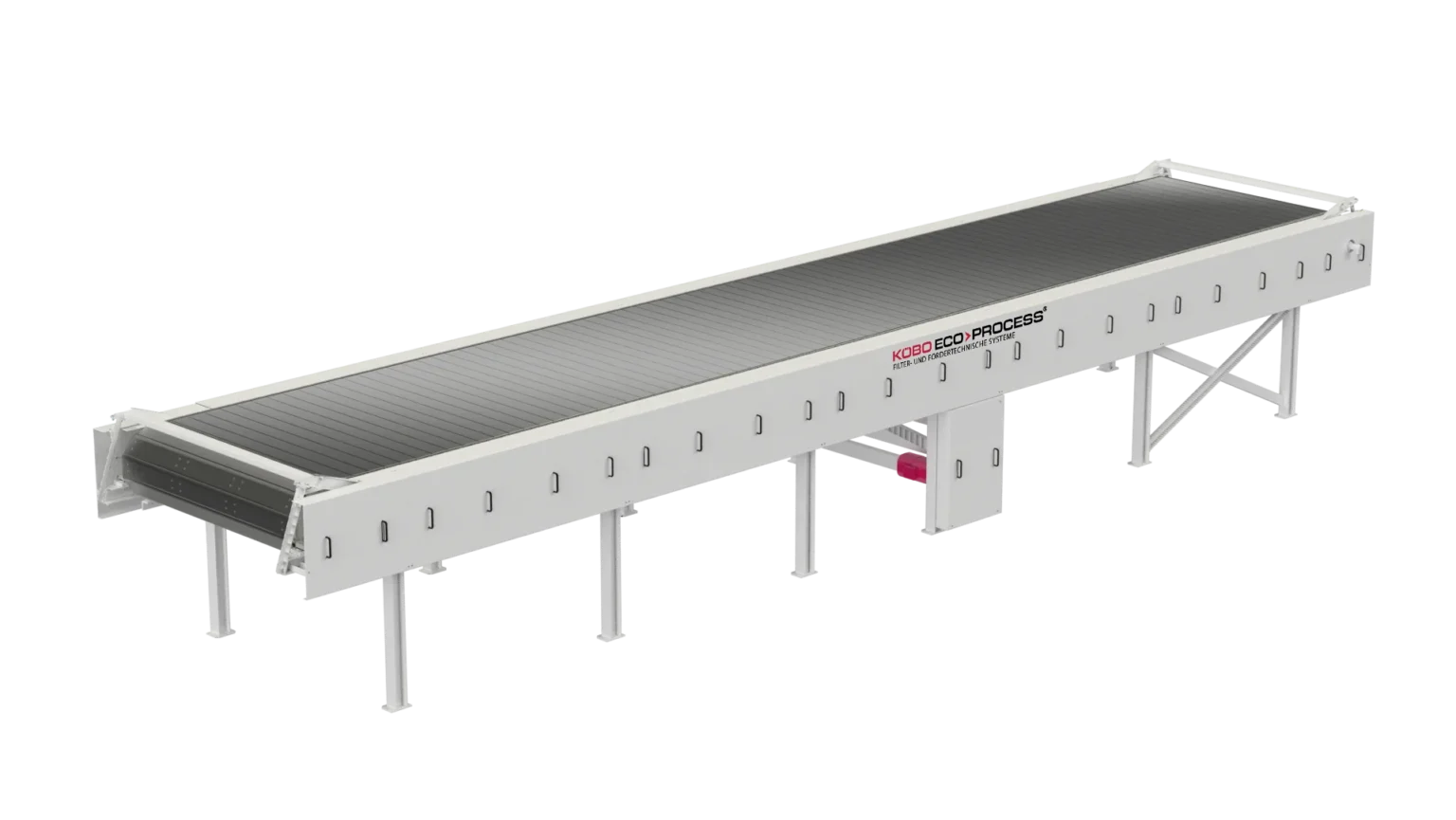

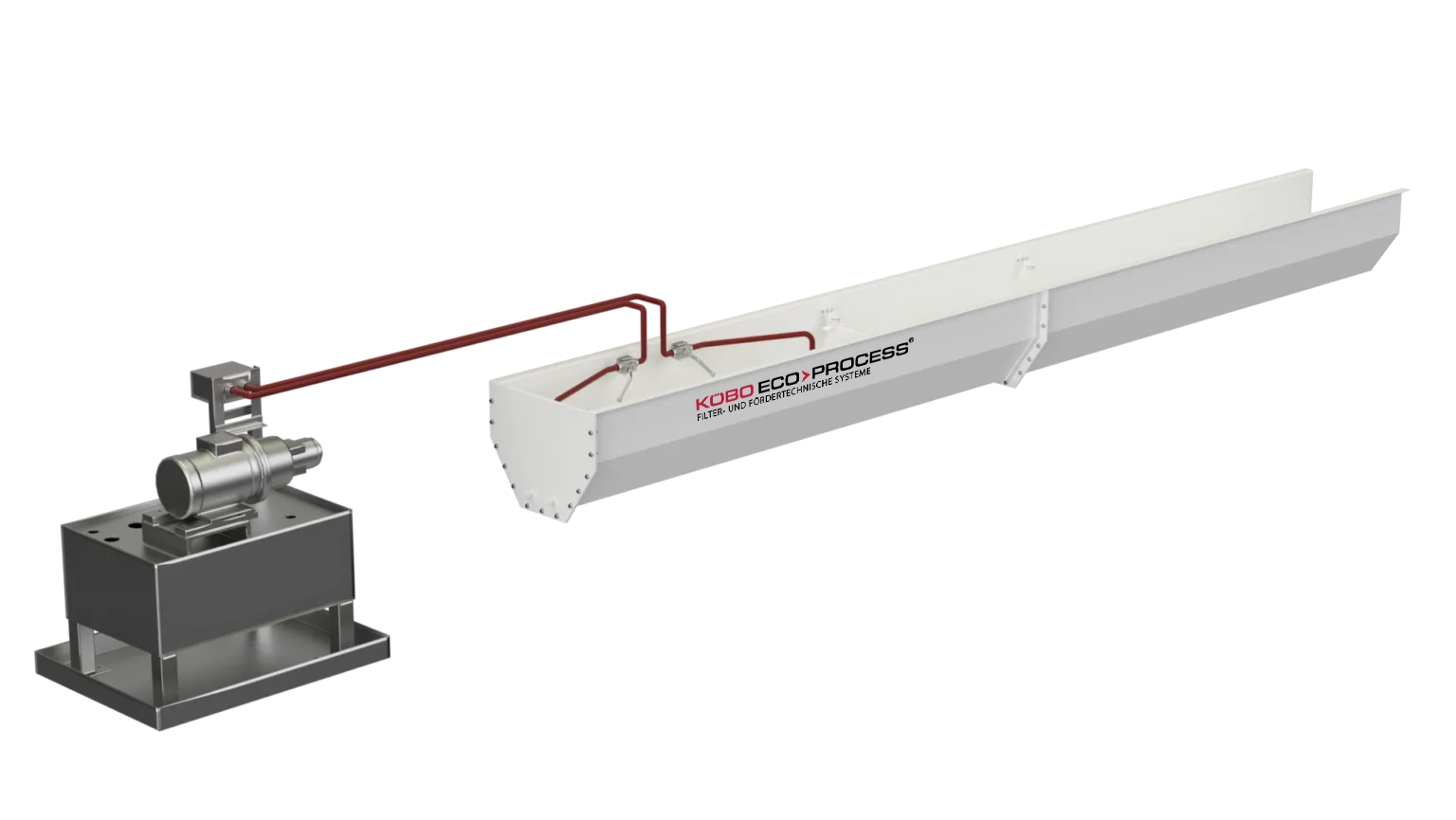

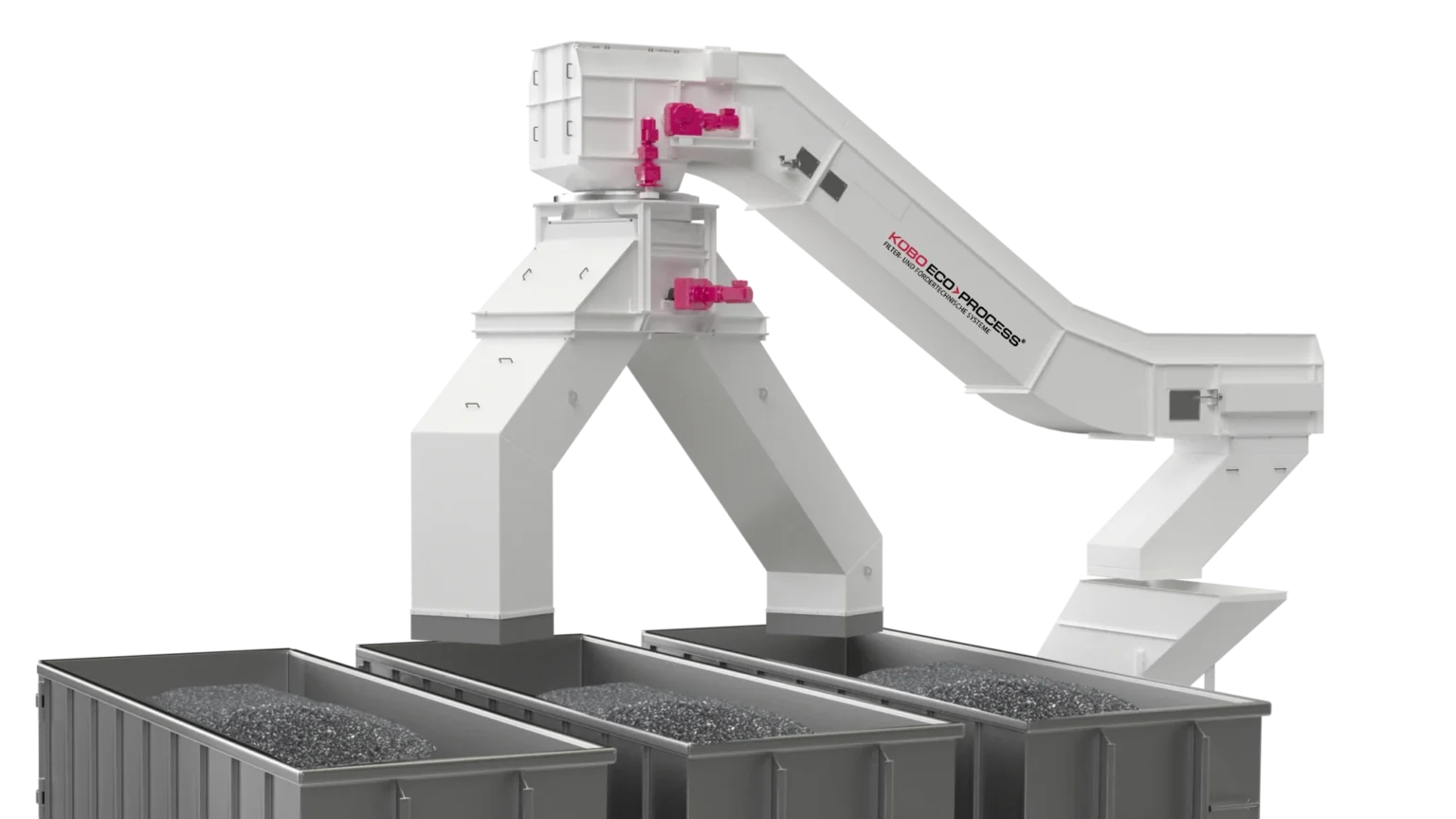

For example, KÖBO ECO>PROCESS currently has a conveyor system consisting of hinged belt conveyors and swivel chutes in Eastern Europe to ensure homogeneous loading of different materials.

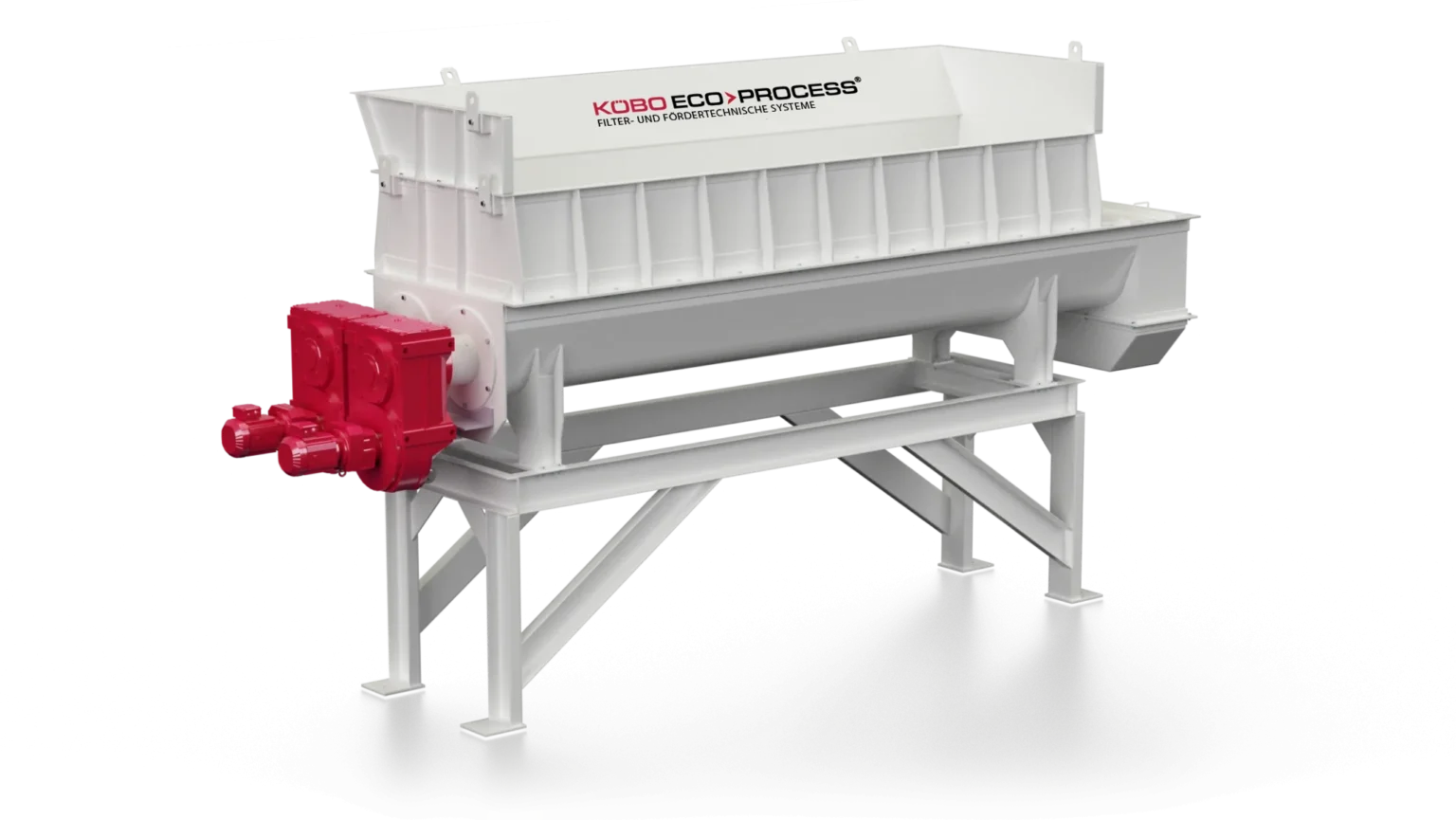

The system is equipped with a fully automatic loading system, which ensures that punching scrap from forming processes, such as aluminium or steel, is removed by type.

A total of 4 different types of material can be processed on the presses, which can be collected by type in 4 roll-off containers.

A material tracking system ensures that the changeovers always take place at the right moment and that no mixed scrap is produced.

The total transport distance is approx. 470 meters and is distributed over a total of 11 conveyor belts, each with a belt width of 1500 mm. It is therefore possible to remove up to 30 tons of punching scrap within one hour!

The safety requirements for loading were met by protective fences and safety doors, which only allow access once loading has been safely stopped.